In the highly regulated medical industry, the quality and safety of every component are paramount. For medical silicone rubber products, which often come into direct contact with human tissue or fluids, adherence to stringent quality standards is not just a recommendation—it's a legal and ethical imperative. As a buyer, understanding these critical standards is essential to ensure patient safety, product efficacy, and regulatory compliance. This article will guide you through the key quality standards for medical silicone rubber products and what to look for when making procurement decisions.

![Quality Standards for Medical Silicone Rubber Products: What Buyers Should Know Quality Standards for Medical Silicone Rubber Products: What Buyers Should Know]()

Why Quality Standards Matter for Medical Silicone Rubber Products

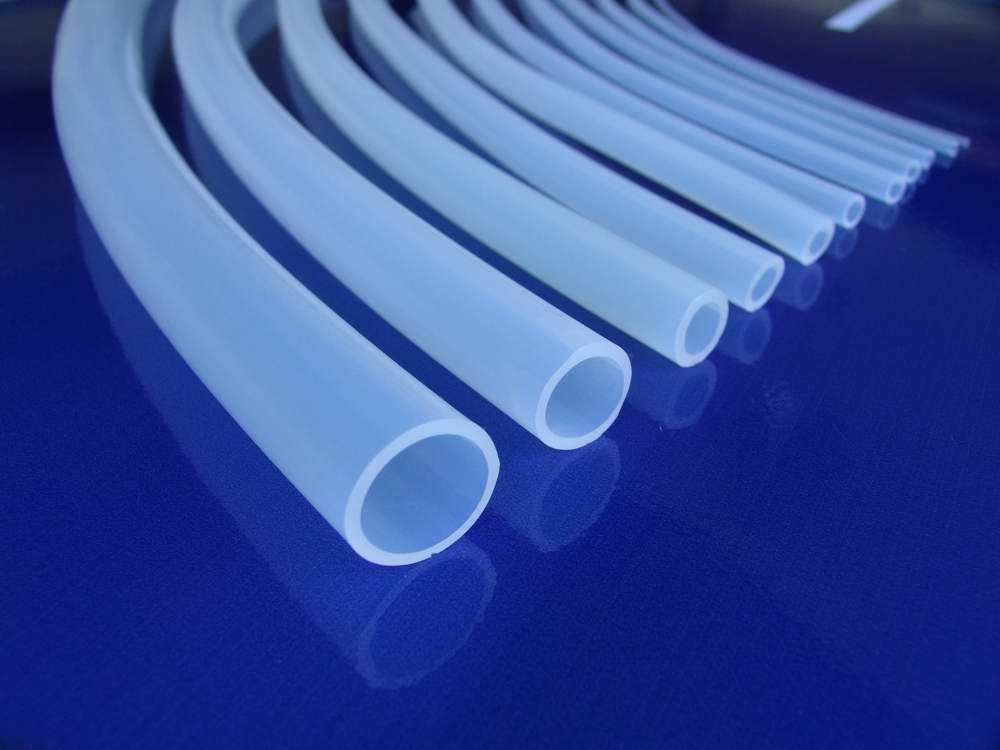

Medical silicone rubber products, such as catheters, tubing, seals, and implantable components, are used in a wide array of critical applications. Any failure in material quality or manufacturing can lead to severe consequences, including patient harm, device malfunction, and costly recalls. Quality standards provide a framework to:

Ensure Patient Safety: By specifying requirements for biocompatibility, sterility, and non-toxicity.

Guarantee Product Performance: By defining material properties, dimensional tolerances, and functional integrity.

Facilitate Regulatory Approval: By aligning with international and national medical device regulations.

Build Trust and Reputation: By demonstrating a commitment to excellence and reliability.

Key Quality Standards and Certifications

When sourcing medical silicone rubber products, buyers should prioritize suppliers who adhere to and can demonstrate compliance with the following critical standards:

1. Biocompatibility Standards (ISO 10993 Series)

Biocompatibility is the ability of a material to perform with an appropriate host response in a specific application. The ISO 10993 series of standards provides a comprehensive framework for evaluating the biological effects of medical devices. For silicone, this typically involves tests for:

Cytotoxicity: Assessing the material's potential to cause cell damage.

Sensitization: Evaluating the potential for allergic reactions.

Irritation: Determining the potential for local tissue irritation.

Systemic Toxicity: Assessing the potential for adverse effects on organ systems.

Hemocompatibility: For blood-contacting devices, evaluating effects on blood components.

What to Look For: Suppliers should provide documentation (e.g., test reports, certificates of compliance) confirming that their medical-grade silicone materials meet the relevant parts of ISO 10993 for the intended application.

2. USP Class VI

USP (United States Pharmacopeia) Class VI is a widely recognized standard for plastics and polymers used in medical and pharmaceutical applications. Materials passing USP Class VI tests are considered to have a high level of biocompatibility. The tests involve both in vitro and in vivo assessments, including systemic injection, intracutaneous injection, and implantation tests in animals.

What to Look For: Verify that the silicone material used in the product is certified as USP Class VI compliant. This is often a prerequisite for many medical device applications, especially those involving prolonged bodily contact.

3. Quality Management Systems (ISO 13485)

ISO 13485 is an internationally recognized standard for quality management systems specific to the medical device industry. It outlines requirements for a comprehensive quality management system for the design and manufacture of medical devices. Compliance with ISO 13485 demonstrates a manufacturer's commitment to quality and regulatory requirements throughout the product lifecycle.

What to Look For: Ensure the supplier's manufacturing facility is ISO 13485 certified. This indicates that they have robust processes in place for design control, risk management, production, and post-market surveillance.

4. Manufacturing Environment (Cleanroom Standards)

Many medical silicone rubber products, especially those for implantable or sterile applications, must be manufactured in controlled environments to prevent contamination. Cleanroom classifications (e.g., ISO Class 7 or Class 8) specify the maximum number of particles allowed per cubic meter of air.

What to Look For: Inquire about the manufacturer's cleanroom facilities and their adherence to relevant ISO cleanroom standards. This is crucial for products requiring high levels of cleanliness and sterility.

5. Sterilization Compatibility and Validation

Medical devices often require sterilization before use. The silicone product must be compatible with common sterilization methods (e.g., autoclaving, EtO, gamma irradiation) and maintain its physical and chemical properties after sterilization. Furthermore, the sterilization process itself must be validated.

What to Look For: Confirm the recommended sterilization methods for the product and request validation data to ensure the silicone material's integrity and the product's sterility assurance level (SAL) are maintained post-sterilization.

6. Material Traceability

Full traceability of raw materials and manufacturing processes is vital in the medical industry. This allows for quick identification and recall of affected products in case of a quality issue.

What to Look For: A reputable supplier should have a robust traceability system that tracks raw material batches, production dates, and quality control records for each product batch.

![Quality Standards for Medical Silicone Rubber Products: What Buyers Should Know Quality Standards for Medical Silicone Rubber Products: What Buyers Should Know]()

Jinan Chensheng Medical: Adhering to the Highest Quality Standards

At Jinan Chensheng Medical Silicone Rubber Product Co., Ltd., quality is at the core of everything we do. As a specialized enterprise with a long history in producing medical macromolecular products, we are committed to upholding the most rigorous international quality standards to ensure the safety and efficacy of our medical silicone rubber products.

Our Commitment to Quality:

Certified Biocompatibility: Our medical-grade silicone materials meet or exceed USP Class VI and ISO 10993 standards, ensuring superior biocompatibility for all patient contact applications.

ISO 13485 Certified Manufacturing: Our production facilities operate under a strict ISO 13485 certified quality management system, guaranteeing consistent product quality and regulatory compliance.

Cleanroom Production: We utilize advanced cleanroom environments for manufacturing critical medical components, minimizing contamination risks.

Precision Engineering: Our state-of-the-art manufacturing processes ensure tight tolerances and consistent performance for every product.

Comprehensive Quality Control: From raw material inspection to in-process checks and final product testing, we implement stringent quality control measures at every stage.

Customization with Quality Assurance: We offer extensive customization capabilities, always ensuring that tailored solutions meet the same high-quality standards as our standard products.

By choosing Jinan Chensheng Medical, buyers can be confident that they are partnering with a manufacturer that prioritizes patient safety, product reliability, and regulatory adherence. We are dedicated to providing medical silicone rubber products that meet the highest global standards.

Conclusion

For buyers in the medical industry, understanding and verifying adherence to quality standards for medical silicone rubber products is non-negotiable. Biocompatibility, robust quality management systems, controlled manufacturing environments, and validated sterilization processes are all critical indicators of a reliable supplier. By prioritizing these factors, you can ensure that the medical devices you procure are safe, effective, and compliant with global regulations. Jinan Chensheng Medical is your trusted partner for high-quality medical silicone rubber products, offering the expertise and commitment to excellence you need. We invite you to contact us to learn more about our quality assurance processes and how we can meet your specific product requirements. We look forward to your inquiry.