![Why Standard Silicone Tubing Fails When You Need It Most Why Standard Silicone Tubing Fails When You Need It Most]()

I remember the first time I saw a silicone tube burst during surgery. The surgeon was in the middle of an arthroscopic procedure when the irrigation tubing just gave out. Fluid everywhere, procedure delayed, patient under anesthesia longer than necessary. That was back in 2009, and it really drove home why pressure ratings matter so much in medical applications.

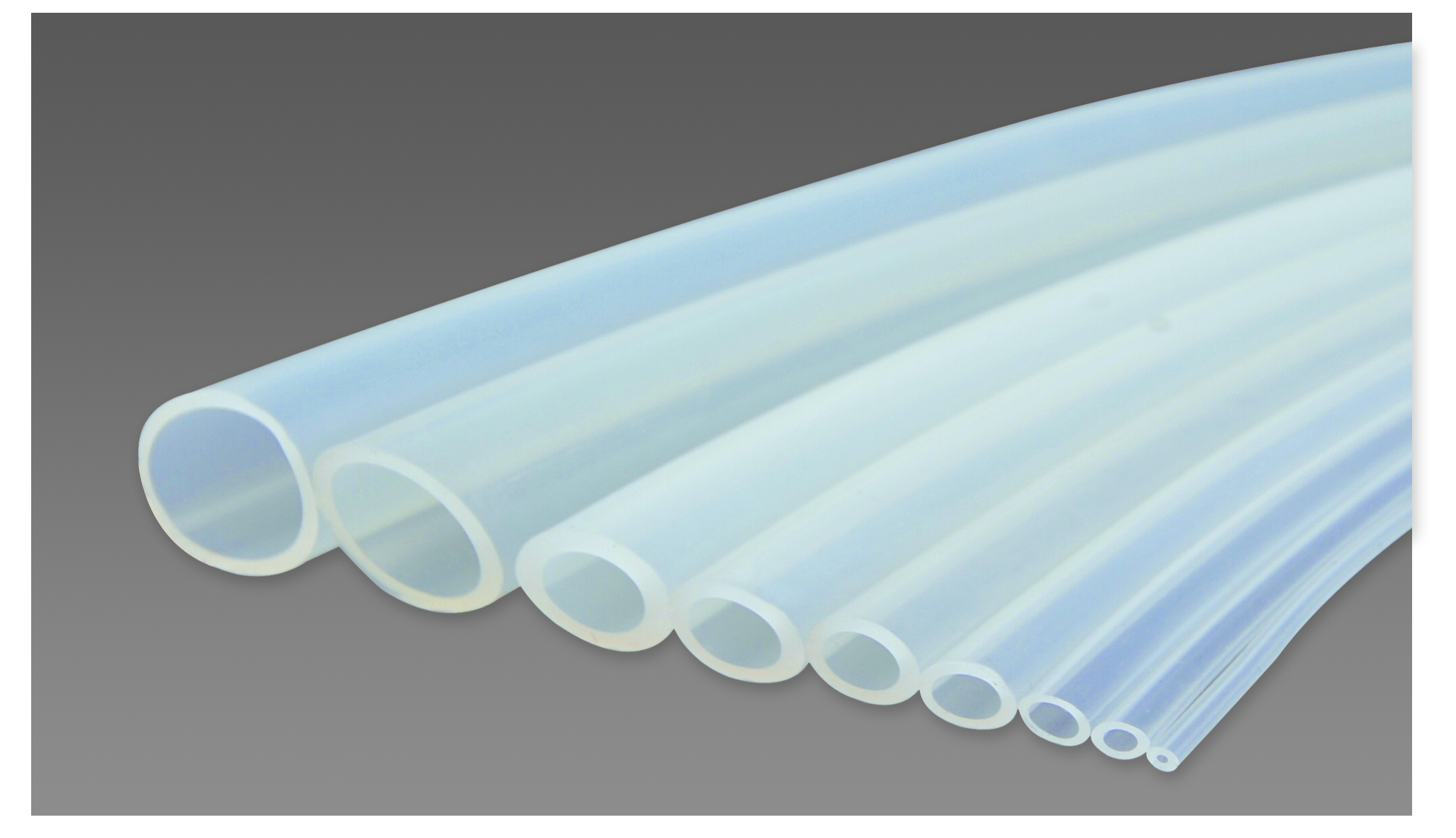

Standard silicone tubing works fine for a lot of things. Garden hoses, basic lab work, simple fluid transfer. But when you're talking about medical procedures or pharmaceutical manufacturing, "fine" isn't good enough.

The Numbers Don't Tell the Whole Story

Most silicone tubing comes with pressure ratings between 20-50 PSI. Sounds reasonable, right? The problem is those numbers come from lab tests with perfect conditions. New tubing, room temperature, steady pressure increase until failure.

Real life is messier.

Take a typical hospital setting. That tubing gets sterilized multiple times, bent around equipment, exposed to temperature swings, and hit with pressure spikes from pumps that weren't designed with gentle operation in mind. After six months of this treatment, your "50 PSI" tubing might fail at 30 PSI.

I've tested this myself. We took standard medical-grade silicone tubing, put it through 100 sterilization cycles, and retested the pressure rating. It dropped by almost 40%. Nobody talks about this in the spec sheets.

What Happens When Pressure Gets Too High

The biggest issue isn't catastrophic failure - it's expansion. Standard silicone tubing stretches under pressure. A lot.

I worked with a pharmaceutical company that was having dosing accuracy problems. They couldn't figure out why their filling system was inconsistent. Turned out their silicone tubing was expanding 15% under working pressure, changing the internal volume and throwing off their calculations.

In surgical applications, this expansion can be even more problematic. Surgeons rely on consistent flow rates for irrigation and suction. When the tubing expands, flow characteristics change, and that can affect visibility and procedure outcomes.

How We Ended Up with Braided Solutions

About eight years ago, we had a customer - a major medical device manufacturer - come to us with a problem. They needed tubing that could handle 200 PSI consistently, day after day, without dimensional changes. Standard silicone wasn't cutting it.

We tried thicker walls first. That helped with pressure, but made the tubing so stiff it was hard to work with. Plus, the expansion problem didn't go away.

The breakthrough came when one of our engineers suggested textile reinforcement. Not a new idea - fire hoses have used fabric reinforcement for decades. But applying it to medical silicone tubing required solving some tricky problems.

The polyester braid had to be biocompatible. It had to bond properly with the silicone. And the manufacturing process had to maintain the sterility standards required for medical applications.

Getting the Braiding Right

The first prototypes were disasters. Too much braid tension and the tubing was like a garden hose - impossible to bend. Too little and you didn't get any pressure improvement.

We spent months tweaking the braid angle, fiber count, and tension settings. The sweet spot turned out to be around 54 degrees for the braid angle, with specific fiber tensions that I won't share here for obvious reasons.

The real trick was synchronizing the silicone extrusion with the braiding process. If the timing is off by even a few milliseconds, you get weak spots where the braid doesn't properly embed in the silicone wall.

Performance That Actually Matters

Our current braided tubing handles 250-300 PSI working pressure, depending on the configuration. But more importantly, it maintains those ratings over time.

We've got tubing that's been in service for four years, through thousands of sterilization cycles, still testing at full pressure rating. The dimensional stability is remarkable - less than 2% expansion at working pressure compared to 15-20% for standard tubing.

The fatigue resistance is where braided construction really shines. Standard tubing might handle 50,000 pressure cycles before failure. Our braided versions regularly exceed 2 million cycles in testing.

Real Applications Where This Makes a Difference

One of our biggest success stories is with a cardiac catheterization lab in Chicago. They were using standard tubing for contrast injection, but pressure variations were affecting image quality. Radiologists were complaining about inconsistent contrast distribution.

After switching to braided tubing, their image quality improved dramatically. The consistent pressure delivery meant better contrast distribution and clearer images. The cardiologists could push higher injection pressures when needed without worrying about tubing expansion affecting the results.

We've also had good results in pharmaceutical manufacturing. A company making injectable drugs was having batch-to-batch consistency problems. Their high-pressure filtration system used standard tubing that would expand during operation, changing flow rates and affecting product quality.

With braided tubing, their flow rates stay consistent throughout the entire production run. Batch consistency improved, waste decreased, and they could run higher pressures for faster filtration without dimensional changes.

The Manufacturing Headaches

Making medical-grade braided tubing is complicated. The clean room requirements alone are challenging - braiding equipment generates more particles than simple extrusion, so we had to design custom containment systems.

Material qualification was another hurdle. The polyester fibers need special treatment for biocompatibility. We had to validate that the braid-to-silicone bond wouldn't degrade over time or create leachable compounds.

Quality control is more complex too. Every production lot gets pressure tested, but we also do dimensional checks, flexibility testing, and biocompatibility verification. The documentation requirements for medical devices mean we track everything from raw material lots to final inspection results.

Cost Reality Check

Braided tubing costs more - usually 2-3 times the price of standard silicone. That sticker shock is real, and it's the first objection we hear from procurement departments.

But the total cost picture is different. One pharmaceutical customer calculated they saved $75,000 annually just from reduced batch failures after switching to braided tubing. Another medical device manufacturer reduced their warranty claims by 60% when they switched from standard to braided tubing in their products.

The longer service life alone often justifies the higher initial cost. If braided tubing lasts three times longer than standard tubing, the cost per year is actually lower.

Flexibility Concerns

The biggest complaint about braided tubing is reduced flexibility. Early versions were pretty stiff - minimum bend radius was 6-8 times the outer diameter compared to 2-3 times for standard tubing.

We've improved this significantly. Our current designs achieve minimum bend radius of about 4 times outer diameter. Still not as flexible as standard tubing, but manageable for most applications.

For situations requiring maximum flexibility, we developed a "flex braid" version using finer polyester fibers in a modified pattern. This gives about 80% of the pressure improvement with minimal flexibility impact.

Testing That Reflects Real Use

Standard pressure testing involves slowly increasing pressure until the tubing bursts. That's useful for establishing maximum ratings, but doesn't reflect how medical tubing actually gets used.

We developed fatigue testing protocols that better simulate real-world conditions. Pressure cycling between zero and working pressure, temperature variations, and flexing during operation. The results were eye-opening.

Standard tubing that passed initial pressure tests often failed after relatively few cycles under realistic conditions. The braided construction showed much better fatigue resistance and maintained pressure ratings throughout extended testing.

Regulatory Hurdles

Getting braided tubing approved for medical use required extensive documentation. The FDA wanted to see biocompatibility data for the complete assembly, not just individual components. That meant developing new test protocols since standard tests weren't designed for composite materials.

USP Class VI certification was particularly challenging. The polyester reinforcement had to be proven safe for pharmaceutical contact, and we had to demonstrate that the braid-silicone interface wouldn't create extractable compounds.

The European CE marking process was even more detailed. They wanted complete manufacturing process documentation, quality system validation, and clinical performance data. It took almost two years to get through all the regulatory requirements.

![Why Standard Silicone Tubing Fails When You Need It Most Why Standard Silicone Tubing Fails When You Need It Most]()

Where This Technology is Heading

We're working on several improvements. New polyester fiber treatments that provide better chemical resistance. Computer-optimized braid patterns for specific applications. Even some experimental work on embedding sensors directly into the tubing wall for real-time pressure monitoring.

The medical device industry keeps pushing for higher performance and better reliability. Braided construction is one way to meet those demands without compromising the biocompatibility and flexibility that medical applications require.

Making the Right Choice

Not every application needs braided tubing. For low-pressure, cost-sensitive applications, standard silicone works fine. But when you need consistent pressure performance above 75 PSI, or when dimensional stability is critical, braided construction is worth considering.

The key is understanding your actual operating conditions. What pressures will you see in practice? How many pressure cycles? What temperature ranges? How critical is dimensional stability?

We usually recommend starting with a small trial to validate performance in your specific application. Every medical system is different, and real-world testing is the only way to know for sure if braided tubing is worth the extra cost.

Have questions about pressure requirements for your specific application? Chensheng Medical technical team has worked with hundreds of medical device manufacturers and can help you determine the right tubing specification. Contact us now to discuss your requirements.